The challenge of managing wastewater residuals

Treating waste water from residential, commercial and industrial sources as well as storm water poses enormous challenges and costs to the municipalities that operate waste water treatment plants (WWTP). Sewage sludge, a by-product of waste water treatment, contains both beneficial organic macro nutrients such as nitrogen and phosphorus as well as micronutrients. It also contains harmful elements derived from solvents, pesticides, beauty care products, cleaning products, and pharmaceuticals, which get flushed down toilets and drains. Some of these can be minimized through different stabilization processes, but other elements persist. The public is increasingly vocal about how and where residuals from WWTPs are applied due to odors and emerging constituents of concern in sludge and biosolids. Regulators are also increasing standards for biosolids recycling in an effort to reduce contamination of water sources and soils. This has sent many WWTP operators on a quest to find improved stabilization and disposal options. Carbonization of biosolids may be a key technology which could provide many advantages over current practices.

Current Practices for Wastewater Residual Management

WWTP operators have a handful of options for the management of sewage including land application, landfilling, composting, lime stabilization, incineration, and anaerobic digestion. Benefits and drawbacks of the most common methods are discussed below.

Land Application

The oldest practice known to man for disposal of human waste is land application. Traditionally land application has been one of the most common (55% in the US) and lowest cost disposal methods for sludge or biosolids although this is largely dependent on proximity to where sludge is spread. Utilizing the macro and micro nutrients in sludge has been a cost-effective way for farmers to reduce the need for fertilizers. However public perception and regulatory oversite has instigated a shift away from this disposal method at least as far as application to land used for growing food. Other factors including application rates, seasonal restrictions, pH of the waste and nutrient management aimed at protecting watersheds restrict how, when and where biosolids can be applied.

Although some developing world countries have few regulations when it comes to land application of biosolids, many countries in Europe forbid it. Regulations in Europe and elsewhere stipulate strict heavy metal thresholds and nutrient loading rates when it comes to land application of any soil amendments . However certain materials found in biosolids are currently unregulated, and in many cases untracked, that are emerging as constituents of concern. These include PCBs, pathogens (e.g. fecal coliforms, salmonella), bacteria (e.g. E.coli), solvents, dioxins, pesticides, microbeads, microfibers, and heavy metals (e.g. copper, nickel, zinc, etc.). Some of these contaminants persist throughout the waste water treatment cycle and sludge stabilization process. Sludge which is treated is often referred to as ‘biosolids’ to differentiate it from untreated sludge. Once applied to soils, these contaminants can find their way into plants and ground water as well as both land and aquatic animals leading to long term negative impacts on entire eco-systems if not properly managed.

Landfill

Many WWTP operators send their residuals to landfills as they are unable to find other outlets for it. In the U.S. more than 2 million tons of sludge/biosolids are sent to landfills (NEBRA 2004). This disposal method is both costly and comes with a heavy carbon footprint due not only to the transportation of residuals but also due to fugitive methane emissions related to decomposing biosolids. The extremely high moisture content of sludge and biosolids creates some challenges for landfills in terms of spreading solids, and odors can be a concern. The quality of landfill leachate is also negatively impacted by the pathogens and heavy metals found in biosolids.

Incineration

In Europe roughly 21% of WWTP dispose of sludge via incineration (Kellessidis et al., 2012) while less than 200 of nearly 16,000 facilities in the US do so. Incineration can reduce residuals by 70 - 95% (US DOT, NYDEC). The resulting sludge ash is most often landfilled but has found application in some areas as a filler for cement, for use in road construction or as daily landfill cover. While energy is required during the start-up phase of incineration, the heat produced becomes largely self-sustaining for most of the processing period. Concern over emissions can often be mitigated by emission control technologies. Although incineration of sludge has a lower carbon footprint than land filling, valuable nutrients (N, P) are wasted. It should be noted that there are emerging technologies capable of recovery P from ash which are becoming mandatory in some places.

Anaerobic Digestion

Anaerobic digestion of sewage sludge provides many environmental and financial benefits. The overall amount of residuals is reduced by up to 55% (Wong et al., 2011) which translates into reduced transportation costs and tipping fees for landfilling biosolids as well as reduced wear and tear on roads. This can be a significant savings to a plant’s bottom line as the cost of landfilling continues to rise. Odors are reduced, though not eliminated and the thermal conditioning which occurs within the AD reduces though does not completely eradicate certain elements of concern. Perhaps most importantly, the biogas generated reduces the amount of electricity that municipalities must purchase from the grid to run the WWTPs. This can be a considerable cost savings as the energy usage from WWTPs can often account for 40% or more of the total energy budget for some cities.

Despite all of these benefits, AD technology is still not prevalent in many parts of the world due to steep up-front capital costs and the current low cost of natural gas. In the US the percentage of WWTP’s with ADs is estimated at less than 10% (Lono-Batura et al., 2012). While Europe has more than 10,000 ADs converting organic waste into biogas, few are used for digesting sewage sludge.

Carbonization can improve management of residuals

Carbonization of biosolids could provide substantial benefits to WWTPs. Although relatively few examples currently exist for pyrolyzing or gasifying biosolids, R&D activities are increasing. In Europe the EU funded “PyroChar” a multi-year, multi-stakeholder project aimed at designing all needed components for pyrolyzing biosolids for small communities.

By-products of thermal conversion of sewage sludge include synthetic gas (syngas), bio-oil and pyrolysate (the chared solid). The benefits of carbonized biosolids are discussed below. The benefits and uses of the other byproducts is beyond the scope of this article.

Carbonized sewage/biosolids

While carbonized biosolids contain valuable nutrients such as phosphorus, they contain relatively low levels of carbon as compared to other feedstocks used for biochar production. Given the low carbon content, carbonized biosolids may or may not be considered as biochar depending on the standards used for classifying biochar. Under the International Biochar Initiatives (IBI) Biochar Standards, if all other properties fall within acceptable ranges, biosolids char could be considered as a Class III biochar (IBI 2011). The European Biochar Certificate (EBC, 2012) Standards have a higher threshold for carbon content. To be considered as biochar, chars must have at least 50% carbon. For chars below this amount, they are denoted as ‘pyrolysis ash containing biochar’ or ‘pyrolysates’.

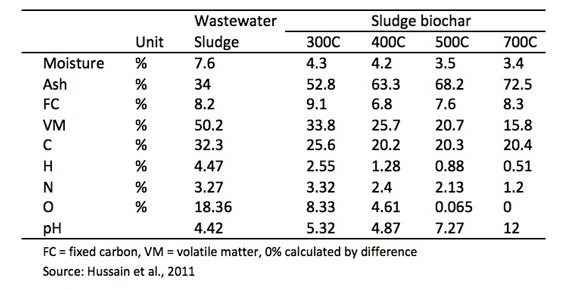

The actual amounts of carbon and other elements in sewage derived char will vary considerably depending on the production temperature as can be seen in the table below (Hussein et al., 2011).

TABLE 1: Proximate, ultimate and agronomic properties of wastewater sludge & sludge biochar

Benefits of Carbonized biosolids

GHG reductions

The amount of greenhouse gas (GHG) emissions which result from WWTP are estimated to account for 2.8% of total global GHG emissions. WWTPs use enormous amounts of energy to process wastewater causing large CO2 emissions. Methane caused by degrading organic material and N2O caused by degradation of nitrogen components in the wastewater (e.g., urea) can be considerable. Although these can be significant, they are quite variable depending on the disposal method used. Landfilling generates the highest emissions and land-application the lowest (Miller-Robbie et al., 2015).

Converting biosolids to char eliminates CH4 emissions related to landfilled residuals as no further decomposition would occur. Further reductions related to reduced transportation of residuals would also improve the carbon footprint of WWTPs. Given that the carbon in many biochars is fairly recalcitrant, landfilling or land application could represent a carbon sequestration opportunity, though further research is needed to understand and measure longevity of this particular type of char in different soils and in landfills. Carbonized biosolids would also greatly reduce the amount of leachate produced at landfills which can be costly to manage. Biochar will also adsorb CH4 emitted from other organic material in landfills. Thus carbonized biosolids could be particularly useful to use when closing landfills that do not have methane capture technology in place.

Toxin reductions

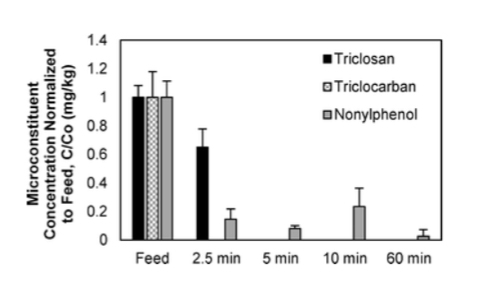

Triclosan (TCS) and Triclocarbon (TCC) are antimicrobials commonly found in toothpaste, soap, shampoo, mouthwash and pesticides. These elements persist in sludge and biosolids and are toxic to certain aquatic organisms. Nonylphenol (NP) is a chemical compound frequently found in laundry and liquid detergents which is an endocrine disruptor. TCS, TCC and NP are not currently regulated but are commonly found in sewage sludge and are contaminants of emerging concern if sludge is applied to land. Pyrolysis can eliminate certain antimicrobials and sulfactants (Ross et al., 2015) when the correct temperatures and residence times are used. The length of time sludge spends in the reactor also influences contaminant reduction as can be seen in Figure 1.

Fig. 1 Impact of pyrolysis reaction time on removal of TCS, TCC, and NP from biosolids during pyrolysis at 500C. Source: Ross et al., 2015

Another persistent micro-pollutant is estrogen which is found in medicines (e.g. birth control) and livestock waste. Estrogen has been found in biosolids and anaerobically digested biosolids and has been found to have negative impacts such as causing intersexing of aquatic animals. Hoffman et al. (2006) found that pyrolysis at temperatures above 400C could reduce estrogen levels in sludge by >95%. With higher pyrolysis temperatures estrogen levels and other organic pharmaceuticals can be eliminated though more research is needed to define the pryrolysis treatment conditions necessary to obtain these results for selected substances.

Reduced disposal costs

Hussain et al. (2010) found that pyrolysis can reduce sewage volume by nearly half at higher temperatures. Tipping fees and transportation of biosolids can be substantial for WWTPs. For example, one small WWTP in upstate NY spends nearly $300,000 per year to landfill 4,500 tons of biosolids per year. So even if no markets were to be found for the biosolids char, the cost savings from reduced disposal costs could be substantial.

Odor mitigation

Nuisance odors occur throughout most of the wastewater treatment process including during thickening, digestion, dewatering, storage, truck loading, transportation, drying, composting, etc. (US EPA 2000). As micro-organisms break down the amino acids and carbohydrates found in sewage sulfur, ammonia and other malodorous compounds are emitted. Such odors impact quality of life and property values and have led to an increase in local ordinances that ban land application of biosolids. While the odors during the initial processing stages would not be impacted, carbonizing sludge and biosolids would eliminate this problem completely at disposal sites.

Markets for Carbonized biosolids

Soil application

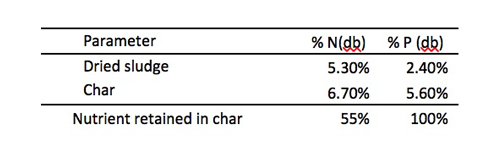

Pyrolysates made from biosolids could be land applied much as biosolids currently are but without the negative impacts. The thermal conversion process effectively reduces certain constituents of concern yet retains at least part of the nutrients and carbon. Phosphorus in biosolids char is to a good extent plant available and could render the char into a type of slow release fertilizer while also reducing the risk of leaching (Bridle et al., 2004). While a good portion of N is retained, Bridle et al. (2004) found it to be insoluble at least in the short term.

Table 2 Nutrient levels in sludge and char, source: Bridle et al., 2004

The carbon in the char is more recalcitrant than carbon in biosolids and could potentially help improve soil carbon levels over the long term. As can be seen in table 1, the pH of biosolids is acidic whereas the pH of biochar ranges widely depending on production temperatures. It is feasible that WWTPs could customize the pH in biosolids char for particular land application needs. Using different production parameters and post-processing technologies it is possible to create a range of pH from a low pH near 5 up to a char with a high pH of more than 10. While certain heavy metals would be retained in the char in a more concentrated form, they would be less mobile than they are in sewage sludge (Liu et al., 2013).

Using the biochar classification scheme developed by Camps-Arbestain et al. (2015) a 50/50 mix of pyrolyzed biosolids and wood chips would be a class 2 (mid-range) fertilizer due to P and Mg content; a class 4 (highest class) liming agent and a class 1 (lowest class) carbon storage material.

Applying a dryer material such as charred biosolids would likely be easier on farm equipment than applying higher moisture content biosolids. It would also be safer for farm workers in terms of eliminating the risk of pathogen contamination. Odors would also be eliminated which would be a welcome change for all neighboring communities where biosolids are currently applied.

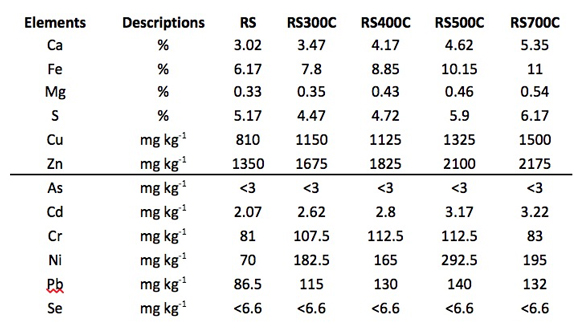

Some studies (Hossein et al., 2010) have found that sludge char can improve yields, especially when combined with fertilizers. Hossein et al. (2014) found that fertilizer enhanced sludge char showed an increase of 167% in cherry tomato production compared to a non-fertilized control, 27% over the fertilized control and 60% over the non-fertilized sludge char. They assessed bioavailability of heavy metals and most were well below permitted maximums with the exception of cadmium which was at the maximum allowable amount in Australia. They also showed, as can be seen in Table 3, that increased production temperatures generally, though not always, tended to increase concentrations of certain micro-nutrients and heavy metals.

Table 3: Means for certain nutrient concentrations & metals of wastewater sludge and biochars. Source: Hussein et al., 2010

However Van Wesenbeeck et al. (2014) showed that certain pyrolyzed sludge chars retain metals that are above permitted levels in some areas and therefore cannot be used for land application. They found that some metals are released during thermal conditioning (e.g. mercury) while others were retained. In their studies zinc, molybdenum and chromium were above allowable levels in Hawaii and cadmium, copper, nickel and zinc were above maximums permitted in Belgium.

Co-product for power plants

Using low temperature carbonization technology, a WWTP in Hiroshima, Japan creates a high calorie, low odor char which is sold to a coal fire plant resulting in an estimated reduction of 6,400 tons of CO2 (Matsumiya 2012). Another plant in Tokyo has been producing 8,700 tons of sewage sludge char from 99,000 tons of sewage which is then mixed with coal for energy generation. The sewage is heated at 500C for 1 hour and generates 2,000 kcal kg–1 of heat calorie, which is equivalent to one third of that of coal (Yachigo et al., 2013).

A US company, PHG Energy, installed a gasifier two years ago that carbonizes biosolids mixed with wood waste (70% wood waste, 30% sludge). The resulting 12t per day of charred materials is used to co-fire electricity plants as well. They expect to go live with a second project in the fall of 2016 which will process 64 t per day and produce 34 t per day of char.

Filtration medium

Char from biosolids could potentially be used as a filtration medium particularly those produced at high temperatures. Increased temperature has been found to increase surface area and adsorption properties. Rio et al., (2015) found that sludge char and limed sludge chars could effectively reduce acid and basic dyes and phenol via filtration. Researchers in China found that a blended char of sludge and tea waste could effectively adsorb certain pollutants such as methylene blue, a dye (Fan et al., 2016). Chen et al., (2002) found that pretreating anaerobically digested sewage sludge with a reagent and then pyrolyzing it at 500C created a char with “remarkable micropore and mesopore surface areas and notable adsorption capacities” for certain contaminants.

Reclamation Projects

In the quest for large scale, inexpensive disposal methods, biosolids have been used for reclamation projects to help revegetate mine lands and mitigate erosion and leaching. Fly ash or lime is often added to improve pH and make application of biosolids easier. In Pennsylvania the use of biosolids for reclamation is broadly used. Although other organic substrates might be far more beneficial, biosolids enabled revegetation which helped reestablish wildlife. However some studies have shown that high biosolids application rates negatively impacted water quality. Increases in acidity levels that resulted from biosolids application are linked to increased leachability of Al, Mn, Cu, Ni, Pb and Zn (PennState, 2016).

The low C/N ratio, low pH and odor issues related to the use of biosolids could be moderated if combined with char. The use of charred sludge in lieu of biosolids in reclamation projects would reduce the risks of heavy metal and inorganic N leaching, and it can be expected that soil remediation would be improved using the adsorbing matrix of sewage pyrolysates.

Building materials

Lack of suitable land for application of sludge and fewer landfills that accept sludge has spurred recent research on alternative uses for biosolids including its use in construction materials. Research shows that combining sludge with concrete or sintering it with clay is a viable method of stabilizing heavy metals. (REF) Japan has created a growing market for the use of dewatered sludge as a raw material in the production of Portland cement. Researchers in Brazil have found that small amounts of sewage sludge could effectively be incorporated in roof tiles (Ingunza et al., 2015). Taiwanese researchers baked sewage sludge at 250C and found that using up to 10% torrified sludge could still produce good quality bricks (Weng et al., 2013).

Biochar has also been found to serve as a viable building material and provides various benefits from improved humidity control to insulation (see here in tBJ). Charring sludge would not only reduce volumes, but could provide improved properties for construction materials. It could also provide a possible cascading use scenario, where sludge is charred at WWTPs, then used as a filtration medium at the facility and finally encapsulated in building materials.

Conclusion

As the world’s population continues to grow, so too will the amount of biosolids that need to be managed. Carbonizing this unending supply of biomass could reduce many, if not most, of the negative environmental impacts associated with biosolids: odors, toxic leaching, GHG emissions, etc. In addition charred biosolids could generate a range of new products which could displace current products which have high carbon footprints such as activated carbons used in filtration or light-weight concrete which can safely sequester carbon.

Technology to carbonize high moisture feedstocks such as biosolids has been available for several years but has yet to catch on in most areas of the world. As the cost of organics disposal and the cost of carbon pollution increases, the economics of carbonizing biosolids will inevitably become much more attractive.

References

- Bridle, T.R. and Pritchard, D., (2004). Energy and nutrient recovery from sewage sludge via pyrolysis; ResearchGate – Water Science & Technology

- EBC, 2012. European Biochar Certificate - Guidelines for a Sustainable Production of Biochar. Version 7.1 of 22th December 2015 [WWW Document]. Eur. Biochar Found. URL http://www.european-biochar.org/en/download (accessed 1.12.16).

- Fan, Shisuo, Tang, Jie, Wang, Yi, Li, Hui, Zhang, Hao, Tang, Jun, Wang, Shen, Li, Xuede, (2016) Biochar prepared from co-pyrolysis of municipal sewage sludge and tea waste for the adsorption of methylene blue from aqueous solutions: Kinetics, isotherm, thermodynamic and mechanism, Journal of Molecular Liquids, Volume 220, August 2016, Pages 432–441

- Hoffman, T.C., Zitomer, D.H., McNamara, P.J., (2016) Pyrolysis of Wastewater Biosolids Significantly Reduces Estrogenicity; Journal of Hazardous Materials, Volume 317, Pages 579–584; http://dx.doi.org/10.1016/j.jhazmat.2016.05.088

- Hossein, Mustafa K., Strezova, Vladimir, Chanb, K. Yin, Nelson, Peter F., (2010) Agronomic properties of wastewater sludge biochar and bioavailability of metals in production of cherry tomato (Lycopersicon esculentum), Elsevier - Chemosphere 78 (2010) 1167–1171

- Ingunza, Durante, Del Pilar, Maria, Andressa Dantas, Lima, (2015) Use of Sewage Sludge as Raw Material in the Manufacture of Roofs, International Conference on Civil, Materials and Environmental Sciences

- Rio, S., Faur-Brasquet, C., Le Coq, L., Le Cloirec, P., 2005. Structure Characterization and Adsorption Properties of Pyrolyzed Sewage Sludge. Environ. Sci. Technol. 39, 4249–4257.

- Liu, Taoze, Liu, Bangyu, Zhang, Wei, Nutrients and Heavy Metals in Biochar Produced by Sewage Sludge Pyrolysis: Its Application in Soil Amendment, Pol. J. Environ. Stud. Vol. 23, No. 1 (2014), 271-275

- Lono-Batura, Maile, Qi, Yinan and Beecher, Ned; Biogas Production And Potential From U.S. Wastewater Treatment, BioCycle December 2012, Vol. 53, No. 12, p. 46

- Matsumiya, Yosuke, (2012). Green Energy Production from Municipal Sewage Sludge in Japan Japan Sewage Works Association http://gcus.jp/wp/wp-content/uploads/2014/06/ebd9e233be72625b03c96047573177f9.pdf

- Miller-Robbie,, Leslie, Bridget A. Ulricha, Dotti F. Rameya, Kathryn S. Spencerb, Skuyler P. Herzoga, Tzahi Y. Catha, Jennifer R. Stokesc, Christopher P. Higgins, Life cycle energy and greenhouse gas assessment of the co-production of biosolids and biochar for land application; Journal of Cleaner Production; Volume 91, 15 March 2015, Pages 118–127,

- PennState Department of Ecosystem Science and Management, Use of Biosolids for Mine Reclamation: Assessment of Impacts on Acid Mine Drainage and Nutrient Discharge, 2016; accessed 19th August 2016: http://ecosystems.psu.edu/research/labs/land-analysis/projects/state/use-of-biosolids-for-mine-reclamation-assessment-of-impacts-on-acid-mine-drainage-and-nutrient-discharge

- Ross, John Fate of Micropollutants During Pyrolysis of Biosolids 2014 http://epublications.marquette.edu/cgi/viewcontent.cgi?article=1283&context=theses_open

- U.S. EPA (2000) Biosolids and Residual Management Fact Sheet: Odor Control in Biosolids Managemen

- Van Wesenbeeck, Sam, Prins, Wolter , Ronsse, Frederik, AntalJr., Michael Jerry, Sewage Sludge Carbonization for Biochar Applications. Fate of Heavy Metals Energy Fuels, 2014, 28 (8), pp 5318–5326

- Weng , Chih-Huang , Lin , Deng-Fong , Chian, Pen-Chi (2003) Utilization of sludge as brick materials; Elsevier - Advances in Environmental Research pp 679–685

- Yachigo, Mieko, Sato, Shinjiro (2013) Leachability and Vegetable Absorption of Heavy Metals from Sewage Sludge Biochar INTECH - Soil Processes and Current Trends in Quality Assessment Ch 15, pp 399 – 416

Use of Earthworms for digestion of sludge?

Has any experiments being done on using earthworms to digest organic components of sludge? The worm castings and worms can be used for soil amendment later. A combination of methods ( Biochar, incineration, earthworms, etc.) may be the best approach.