Introduction

One source of confusion for those new to the U.S. customary measurement system is the ounce, a unit used to measure both weight (1 avoirdupois ounce = 28.35 grams) and volume (1 fluid ounce = 29.6 cm3). In an American grocery store, it is easy to purchase the wrong amount of an ingredient because the recipe might list volume ounces and the ingredient might be sold by weight ounces. Converting from weight to volume and volume to weight is possible with information about the material’s density, but these conversions are almost never convenient.

This issue of converting from weight to volume and back again is also seen in communications and commercial activities related to biomass and biochar. For example, biochar researchers might report only mass in journal articles, i.e. “5 g of as received biomass was fed into the reactor, yielding 2 g of biochar.” A large-scale biomass supplier might list prices in dry tons. An extension agent making biochar soil application recommendations might use cubic feet or cubic yards per acre, or cubic meters per hectare. A pyrolyzer for making biochar might be sized by liters or cubic feet. Each unit, weight or volume, is chosen by familiarity and convenience for a specific application. Such differences in units can cause confusion across different sectors of the biomass and biochar industries. In this article, we present a discussion of density, its different definitions and methods for measurement. We include representative density values for reference and some examples of the “amounts” one is likely to encounter in biomass and biochar research and industry.

Density

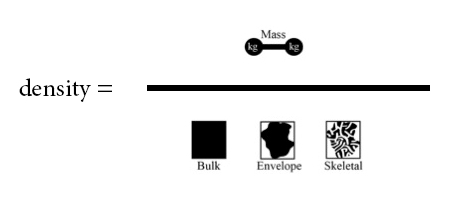

The simplest definition of density is mass divided by volume. Examples of density units are grams per cubic centimeter (g/cm3), kilograms per cubic meter (kg/m3), pounds per cubic foot (lbs./ft3), pounds per cubic yard (lbs./cu yd). The mass component of density is usually clear in definition and is relatively easy to measure. Advances in mass measurements are more often improvements in instrument accuracy, range and precision, rather than changes in measurement method. Volume definitions and measurements, however, are much more nuanced and are the reason for the variation in densities. Volume may refer to the volume of a container holding the bulk material, the “envelope” volume of a single particle, or the volume of the material “skeleton,” excluding pores and voids. Figure 1 shows three different ways that volume can be measured for a porous material; each different volume measurement leads to a different density value. Table 1 gives some examples of densities values for biomass and biochar.

Figure 1. The difference between skeletal, bulk and envelope densities. (1)

Bulk Density

Bulk density is defined by the volume of the container used to hold the sample—this volume includes pore space within and between the sample particles inside the container. To measure bulk density, a container of known volume is weighed empty, filled with sample, and then weighed again; the mass of the sample is divided by the volume of the container. Bulk density is heavily dependent on how the sample particles pack into a container. Bulk density measurement standards, such as ASTM E873 for densified particulate biomass fuels (6) and ASTM E1109 for solid waste fractions (7) have to be very specific about how the sample is poured and leveled, and if any kind of pressure or tapping procedure is used. (Other related methods include ASAE 269.5 for densified materials (8), EN 15103 for solid biofuels bulk density (9), and ASTM D2584 for activated carbons (10).) The practice of tapping the container to ensure repeatable sample packing is why bulk density is sometimes called “tap density.”

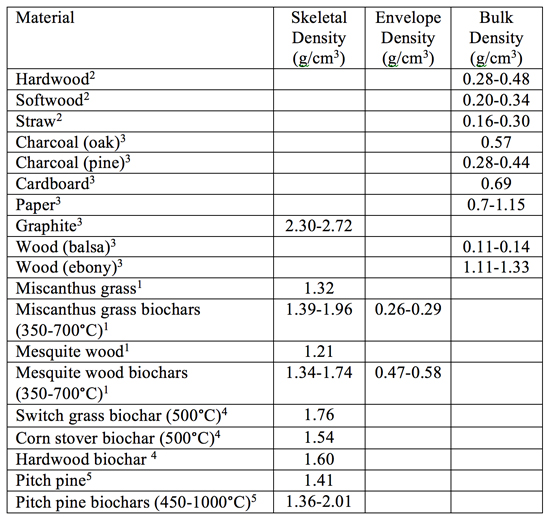

Table 1. Examples of biomass and slow pyrolysis biochar density values. (1 g/cm3 = 1000 kg/m3 = 62.4 lb./cu ft.)

Bulk density is the most commonly used density definition in U.S. biomass and biochar production and sales. A distinction is sometimes made between “dry mass” density, “as shipped” density, and “packed out” density. Dry mass density is the dry weight of the biomass/biochar divided by the volume of biomass/biochar in a full container. Typical values for biochar dry bulk densities range from 5 to 20 lbs. per cubic foot, or 135 to 540 lbs. per cubic yard, or 80 to 320 kg/m3. The sizable difference in values can be attributed to the original biomass feedstock density (11) and the biochar particle size. For example, coconut shell is denser than miscanthus grass and will pack more densely, just as flour will pack more densely than gravel. Shipped density uses the same volume as bulk density but can include the weight of moisture and other non-biochar materials in the container. Shipped density does not account for easily ground materials becoming denser during transport due to shaking and jostling. Packed out density is the weight divided by the volume of the material as it is “packed out” for loading onto a truck or train car. It often includes the weight and volume of the pallet (~50 lbs. or 23 kg), the containers, and the packaging materials such as shrink wrap.

Buyers generally want to know both the dry mass density and the water content to know how much char they are getting, as well as how much moisture they are transporting. This moisture is not necessarily bad. Between 10% and 50% moisture on a dry basis helps to control dust, makes handling easier, and can be required in some markets for safety.

Skeletal Density

Skeletal density is also called true density or particle density because it excludes voids and pore space and measures only the volume of the solid material (12). Skeletal density is generally the most consistent density measurement because it is not affected (theoretically) by sample packing or by particle size. Skeletal density is used for calculations of porosity and engineering calculations involving movement of particles. For example, engineers use skeletal density to determine the gas flow rates needed to fluidize particles in fluidized bed reactor systems and pneumatic particle handling systems.

Skeletal density is directly related to the composition of the solid material. For biochars, skeletal density can provide information about the ash content and the extent of pyrolysis. In general, the density of ash (minerals) is much higher than that of organic materials because the molecular weights of metals (Na at 23 g/mol, and moving up from there) are much higher than the molecular weights of H, C, N and O, at 1, 12, 14 and 16 g/mol, respectively. Assuming that a solid contains a similar number of atoms in a given amount of space, solids containing metals would be much heavier than solids containing only H, C, N and O. Therefore, biochars made from biomass feedstocks with higher ash contents, like rice husks, straw or manure, have higher skeletal densities. For biochars made from the same biomass feedstock, a higher skeletal density is usually associated with more complete pyrolysis at higher temperatures and/or longer reaction times (11). This is because the skeletal density of pure graphite (2.25 g/cm3) (13), the ultimate product of complete carbonization, is higher than the skeletal density of glucose (1.54 g/cm3), a representative component of raw biomass. The density difference, in this case, is caused by more atoms being packed closer together, a function of bond distances, rather than differences in the weights of the atoms.

Skeletal density is measured by gas pycnometry, specifically helium pycnometry for biomass and biochars. Gas pycnometry is the measurement of sample volume based on displacement of air or other gases through a measured amount of another injected gas. The volume of the sample can be determined from the Ideal Gas Law: PV = nRT (pressure * volume = number of moles of gas * the gas constant * temperature in degrees Kelvin). Helium is used as the analysis gas for biomass and biochar pycnometry for three reasons. First, helium is inert. Second, helium is a very small molecule that can penetrate into even the smallest pores of solid samples; this prevents accessible airspaces from being misinterpreted as solid material. Finally, helium does not adsorb to biomass and biochar surfaces; this means that helium does not confuse the pressure measurement by attaching to or detaching from the sample surface during analysis.

Envelope Density

Envelope density differentiates all void spaces into pores between particles and pores within particles. Pore space within particles, “intra-particle pore space,” is included in the sample volume while pore space between particles, “inter-particle pore space,” is not. Envelope volume is the volume the sample occupies if an “envelope” were wrapped around each particle. The values for envelope density for a perfectly non-porous material would be the same as the skeletal density for that material. For porous materials, such as biochar, the envelope density is somewhere between the bulk density and the skeletal density.

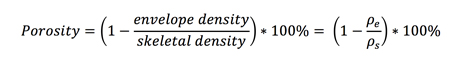

Knowing the envelope density enables the calculation of intra-particle porosity, i.e. what percentage of the particle is solid and what percentage of the particle is pore space. Porosity is calculated by knowing the ratio of the envelope density to the skeletal density and subtracting that from 100% (1):

If the envelope density and the skeletal density are the same, i.e. for a non-porous solid, the porosity is 0%. If the skeletal density is twice that of the envelope density, it means that the same amount of mass takes up twice as much space, i.e. 50% of the particle is air space. Porosity is important for understanding the effects of biochar on soil properties that relate to pores: water holding capacity, aeration, microbial habitat, etc. (Intra-particle porosity is different than the “porosity” used to describe horticultural porous growth media; growth media porosity includes both intra-particle and inter-particle porosity.)

Envelope density can be measured in several ways. The sample could be coated with a sealant, water repellant material, then dipped into a container of water and the displaced volume of water measured. For example, a piece of charcoal could be weighed, dipped into wax, weighed again once the wax had dried (to know the mass and then to calculate the volume of the added wax), then dipped into a container of water, and the volume of displaced water measured. A piece of wood can simply be measured carefully with a ruler or calipers, or dipped into water as it will not absorb a significant amount of water during a short dipping time (14). Another method, originally developed for work with geologic samples, is solid pycnometry. Just like helium pycnometry, the volume of the sample is measured by the displacement of another material; this time the displaced material is a free-flowing, granular solid instead of helium. The idea is that the granular material, when mixed with the sample, can get between the sample particles without penetrating into the particles. This means that the displacing solid particles have to be relatively small compared to the sample particles (1). The sample volume is then calculated by difference.

Figure 2. Wood logs in a staging area prior to size reduction and pyrolysis.

When By Mass and When By Volume?

In most scientific research publications, amounts of material are described using mass (kg, g, mg, etc.) because there is little ambiguity in mass definition or measurement. The volumes of material needed for scientific research are generally small and measuring small volumes exactly is more challenging than measuring small weights. In industrial and commercial applications, on the other hand, volume is often used because solid materials are usually sold in containers or bags with fixed volumes. For materials with low bulk densities, such as biomass and biochar, space requirements are more likely to be the limiting factor compared to weight limits (the opposite is true for very dense materials like steel and concrete). In addition, biomass and biochar generally have the same volume whether they are wet or dry. In between these perspectives are environmental research studies where percentages and concentrations are sometime reported on a weight/weight basis (for example, concentrations of metals in soil in units of mg/kg), sometimes on a volume/volume basis (for example, amounts of water in soils in units of cm3/cm3), and sometimes on a weight/volume basis (for example, concentrations of metals in water in units of mg/L).

Wet Weight, Air-Dry Weight, Bone-Dry Weight, and Oven-Dry Weight

Like most agricultural/forestry/food products, moisture content can vary widely for batches of biomass or biochar. Measuring and reporting dry weight as well as wet weight can help alleviate potential confusion regarding exactly how much water and how much solid a sample contains. The drying method used to measure moisture content affects the terminology used when reporting dry weight. Wet weight, or sometimes “as received weight,” is the weight of the biomass or biochar plus any “raw” and “bound” water in the biomass or biochar. Raw moisture is water that is mixed in with the biomass or biochar but not chemically bound. This water can be removed with gentle heating in dry air; 40°C and 60°C are common temperatures for this kind of drying (15,16). Bound water is chemically bound to the biomass or biochar and therefore, requires heating to temperatures above the boiling point of water (105°C is commonly used) to ensure water removal (17).

Figure 3. Wood chips being conveyed into a holding area prior to pyrolysis.

Freshly harvested, green biomass can have very high moisture contents (often >50% on a wet basis). After harvest, the biomass begins to dry in the field until the moisture content is in equilibrium with the air. This is “air dry” weight and depends on the exposure time, ambient temperature, and relative humidity. In dry locations, air dry samples will contain less moisture than air dry samples in humid locations. Freshly produced biochar is “bone dry” because the temperatures used in pyrolysis are much higher than the boiling point of water; all raw and hygroscopic water has been removed. When fresh biochar is exposed to air (which contains moisture), the biochar will absorb hygroscopic water. The longer the fresh biochar is exposed to air, the more moisture it will absorb, up until its moisture content is in equilibrium with the air’s humidity. Water is sometimes used to quench the pyrolysis reaction, so fresh biochar may contain water from this quenching process. “Oven dry” weight is the weight of the biomass or biochar after it has been dried to a constant weight in an oven; often, oven dry means the higher temperature was used to evaporate all of the hygroscopic water. Oven dry weight is the most commonly used weight in science literature because it is the most repeatable across samples and locations.

Figure 4. Biochar particles after sieving, showing bigger particles (left) and fines (right). Bigger particles can often be easier to handle than fines because they produce less dust.

Examples of Handling and Sales Units

In the U.S., biochar is often handled and sold by cubic foot (28L or 0.028 m3 or 1/27th of a cubic yard), or by cubic yard (0.764 m3), while in Europe, biochar is sold by cubic meter or liter. Biochar is often packed in bags made of sturdy plastic to protect it from moisture, especially flexible intermediate bulk containers (FBIC) or Super Sacks® (see Figure 5). FBICs come in various sizes from 0.5-3 m3, and are often square on the bottom with sides of approximately 35” (~1 m). These bags are usually packed and transported on standard pallets. Biochar is also transported in bulk by trucks and hopper rail cars of various capacities, up to 90 m3 (~120 cu. yd.) and 75-150 m3 (~100-200 cu. yd.), respectively. For easier loading and unloading of loose bulk material, some trucks come equipped with walking floors.

Figure 5. A cubic foot (28.3 l) bag of biochar (left) which would usually weigh 5-20 lbs (2-10 kg). Typical values for biochar dry bulk densities range from 5 to 20 lbs. per cubic foot, or 135 to 540 lbs. per cubic yard, or 80 to 320 kg per cubic meter. Cubic foot (85 l) bags (middle) of biochar packed into a UV cover slip ready for loading onto a pallet. Cubic yard (765 l) bags (right) of wood biochar palletted and ready for transport. These bags would usually weigh 135-540 lbs. (61-245 kg)..

Conclusion

Mass, weight, volume, density and moisture content are all critical for understanding biomass and biochar properties. Different definitions for these properties exist depending on the industry, the measurement method, and the primary goal of the property communication. To ensure effective communication and consistency for both researchers and commercial operations, it is important to understand the differences between the definitions and to recognize the implications of higher or lower reported property values.

References

(1) Brewer, C. E.; Chuang, V. J.; Masiello, C. A.; Gonnermann, H.; Gao, X.; Dugan, B.; Driver, L. E.; Panzacchi, P.; Zygourakis, K.; Davies, C. A. New approaches to measuring biochar density and porosity. Biomass Bioenerg. 2014, 66, 176-185.

(2) Brown, R. C.; Brown, T. R. In Biorenwable Resources: Engineering New Products from Agriculture; 2nd ed.; Wiley-Blackwell: Danvers, MA, 2014, p 94.

(3) CRC Handbook of Chemistry and Physics; 84th ed.; Chemical Rubber Publishing Company: Boca Raton, FL, 2003.

(4) Brewer, C. E.; Schmidt-Rohr, K.; Satrio, J. A.; Brown, R. C. Characterization of biochar from fast pyrolysis and gasification systems. Environ. Prog. Sustain. Energy 2009, 28, 386-396.

(5) Brown, R. A.; Kercher, A. K.; Nguyen, T. H.; Nagle, D. C.; Ball, W. P. Production and characterization of synthetic wood chars for use as surrogates for natural sorbents. Org. Geochem. 2006, 37, 321-333.

(6) ASTM E873-82(2013) Standard Test Method for Bulk Density of Densified Particulate Biomass Fuels. ASTM International: West Conshohocken, PA, 2013.

(7) ASTM E1109-86(2009) Standard Test Method for Determining the Bulk Density of Solid Waste Fractions. ASTM International: West Conshohocken, PA, 2009.

(8) ASABE. ASAE S269.5 Densified Products for Bulk Handling -- Definitions and Methods. American Society of Agricultural and Biological Engineers: St. Joseph, MI, 2012.

(9) CEN. EN 15103 Solid Biofuels Determination of Bulk Density. European Committe for Standardization: Brussels, 2009.

(10) ASTM D2854-09(2014) Standard Test Method for Apparent Density of Activated Carbon. ASTM International: West Conshohocken, PA, 2014.

(11) Chia, C. H.; Downie, A.; Munroe, P. In Biochar for Environmental Management; 2nd ed.; Lehmann, J., Joseph, S., Eds.; Earthscan: London, 2015, p 89-109.

(12) CEN. EN 15150 Solid Biofuels Determination of Particle Density. European Committe for Standardization: Brussels, 2011.

(13) Downie, A.; Crosky, A.; Munroe, P. In Biochar for Environmental Management Science and Technology; Lehmann, J., Joseph, S., Eds.; Earthscan: London, 2009.

(14) ASTM D2395-14 Standard Test Methods for Density and Specific Gravity (Relative Density) of Wood and Wood-Based Materials. ASTM International: West Conshohocken, PA, 2014.

(15) ASTM D4442-07 Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Base Materials. ASTM International: West Conshohocken, PA, 2007.

(16) EBC. European Biochar Certificate-Guidelines for a Sustainable Production of Biochar, Version 6 of 1 Apr 2015. European Biochar Foundation: Arbaz, Switerland, 2012, p 21. http://www.european-‐biochar.org/en/download.

(17) ASTM D1762-84(2007) Standard Test Method for Chemical Analysis of Wood Charcoal ASTM International: West Conshohocken, PA, 2007.

Defining quantities when selling

I admit I have only skimmed this article, but in the end it did not seem to make a clear recommendation with regards to units of measure for char sales. To set a context, in Australia fertilisers, by regulation, must be sold by mass. In contrast soil amendments, like compost, are usually sold by volume. Biochar is usually not classed as a fertiliser unless it has been fortified with nutrients. Variability in density and moisture content is inescapable, unless you always deal with a feedstock that never varies, a process that always produces exactly the same yield and quenched moisture content and store everything in fully sealed vessels ! For this reason we focus on selling by packed volume. For large orders we back this up with photographs and weighbridge weights. We also provide a value for loaded moisture, on request (rarely requested), The former addresses the issue of compaction during transport. The later is often of interest to the end user and certainly of interest to the truck driver if he has load limits to consider. Nevertheless a very handy article to point customers to.