In spring and autumn, when farmers spray their fields with liquid manure, an acrid stench spreads across the countryside. This pungent smell comes especially from ammonia, a volatile nitrogen compound formed from the urea contained in the manure. Large portions of the ammonia, which is corrosive to soil organisms and fine roots, escape into the atmosphere, where it binds to dust particles and returns in the form of acid rain onto fields, forests, cities and water systems, causing major environmental damage.

While some of the minerals in the liquid manure like ammonium, nitrate, urea and phosphate become available as nutrients to the plant, a, significant portion of the nutrients is leached to ground and surface waters, not to mention the climate-damaging gas emissions. Some 50% of the nitrogen is lost by degassing, leaching and erosion between cowshed and field via the manure pit, resulting not only in very low fertilizer efficiency but costly environmental damage. In Germany alone, agricultural ammonia emissions amount to more than 600 000 tons a year.

Due to the outgassing of ammonia and leaching of nitrates, fertilizing with untreated liquid manure results in soil acidification, which in turn greatly impairs the fertility and biological activity of the soil and accelerates the decomposition of humus.

Even more dangerous than soil acidification, however, is when, as a result of using non-treated manure, pathogens from animals’ digestive tracts or from the bacteria strains and fungal spores generated in the rotting manure pit are spread into the fields. Although most disease-causing microorganisms are destroyed by antagonists in the soil, some highly resistant strains of bacteria, fungal spores and other pathogens like Clostridium (EHEC, botulism) survive the entire plant growth cycle and can be ingested by the animals via fodder from these fields. This completes a vicious cycle that gradually breeds more and more resistant pathogens and may endanger both animal and human health.

Modern liquid manure spreaders can considerably decrease nutrient losses and greenhouse gas emissions. But the highly concentrated ammonia still remains harmful to the soil. Pre-treating liquid manure and mixing with biochar may increase fertilizer efficiency by around 50%.

What stinks in the liquid manure?

Most of the nitrogen comes into the manure in the form of urea, which is then converted into ammonia and CO2 (or to ammonium + CO3) through the enzyme urease. Urease is found in animals’ stomachs, in the manure pit and in the soil; which means that the decomposition of urea can take place virtually continuously and everywhere. While conversion in the soil into the important plant nutrient, ammonium, is a desired process and the key to the fertilizing effect, conversion in the manure pit means the loss of the nitrogen and, not least, the acrid stench.

Manure treatment by lactic acid fermentation

Disinfecting the liquid manure, stabilizing the nutrients and thereby preventing the development of odour require:

- binding the volatile nutrients,

- inhibiting the enzyme urease, and

- preventing the proliferation of pathogenic microorganisms.

Lactic acid fermentation, a very old method of preservation, is particularly suited for stabilizing the urea in the manure and preventing it from rotting. During lactic acid fermentation, sugar compounds, which occur in all plant materials and also, in lower concentrations, in liquid manure, are converted by lactic acid bacteria into lactic acid. This conversion lowers the pH down to 3.5 – 4.5, resulting in a highly acidic environment below the survival conditions for most types of bacteria, spore-forming organisms and enzymes.

The prevention of rotting and outgassing is not solely a question of the acid, otherwise one could use any acid to lower the pH. It is of great importance that the acidic environment is produced by lactic acid bacteria, since in this way the remaining sugar compounds in the liquid manure are broken down, depriving competing putrefactive bacteria of the nutrient base and preventing them from multiplying further.

In addition, useful cell components such as nitrogen, phosphorus, sulphur and carbon are stored in the cells of the rapidly proliferating lactic acid bacteria. Nitrogen, phosphorus and sulphur that are stored in the cell tissues of lactic acid bacteria are biologically tied down and no longer volatile. Competing microbes find themselves thus in short supply of all essential nutrients, in an unfavorable, acidic environment.

When the lactic acid bacteria subsequently come with the stabilized liquid manure onto agricultural land, they will in turn be deprived of their survival conditions by the atmospheric oxygen and the higher pH values of the soil, whereby the nutrients stored in their cells will be recycled by other microbes and become available to plants. The result is a truly biologically activated fertilizer.

Historical significance of lactic acid fermentation

Lactic acid fermentation was used already in the Stone Age for preserving food. This was a precondition for the development of a stockpiling economy, which in turn permitted the formation of sedentary societies. Lactic acid fermentation was used to produce sauerkraut, sourdough bread, yogurt, sausage, wine and also for feed silage. It was, however, hardly used for fermenting liquid manure treatment, as in traditional cowsheds no liquid manure was produced and solid manures are better composted than fermented.

Instructions for treating liquid manure with sauerkraut juice and biochar

In order to make use of lactic acid fermentation to ‘conserve’ liquid manure, the manure pit must first be inoculated with a sufficient quantity of lactic acid bacteria. The lactic acid bacteria have to be multiplied in such a way that pH falls below 5. The following procedure has proven successful in practice:

- Empty the liquid manure pit, leaving not more than 25 cm of sediment.

- Inoculate the remaining manure in the pit with 0.2 – 0.5% sauerkraut juice.

- To encourage the multiplication of the lactic acid bacteria, add 1% molasses.

- Mix in 2% biochar for fixing nutrients and toxic substances.

(for 50 m3 of manure sediment this amounts to 100-250 l sauerkraut juice, 500 l molasses and 1 m3 biochar)

Sauerkraut juice contains a very high quantity of lactic acid bacteria and is ideal for inoculation. Instead of sauerkraut juice one can also use bread drink (Brottrunk), silage juice, or EM-A (effective microorganisms). The latter also contains other microorganisms which favorably influence the process. Sauerkraut juice, however, is by far the cheapest means and of assured quality. Today, millions of litres of sauerkraut juice are disposed of, against payment, in wastewater treatment plants. The agronomic use of sauerkraut juice would also be a good example for the closing of nutrient cycles.

Molasses are needed so that the lactic acid bacteria in the sauerkraut juice can multiply thousands of times and so optimally adjust the microbial environment of the liquid manure. If, however, the manure pit is too full, it will not be possible to shift the microbial environment from putrefying to lactic acid fermentation, because the other microbial strains will be too dominant and the lactic acid bacteria will not prevail in spite of the molasses. It is therefore absolutely necessary to pump the pit as empty as possible before initiating the lactic acid fermentation.

Once the pH of the liquid manure drops below 5 through the effect of lactic acid fermentation, the conversion of urea to ammonia is prevented, rot-causing bacteria are suppressed, the liquid manure no longer stinks and the nutrients are retained and fixed.

Effect of biochar

The high specific surface area and the high cation exchange capacity of biochar makes it very efficient in binding ammonium and ammonia and other odourous and often toxic substances. For this reason the use of biochar, even without lactic acid fermentation, is rapidly effective. Through the use of biochar most of the nitrogen in the manure can be stored available for plants. The leaching of manure nutrients in the soil is slowed significantly, which not only protects the groundwater, but also and in particular prevents the acidification of the soil. Biochar-treated liquid manure promotes soil activity and humus formation. Soils are built up over the longer term instead of being eluviated by toxic liquid manures. Overall, the fertilizer efficiency of liquid manure may nearly doubling with biochar.

Although the treatment of manure with biochar is already effective on its own, its combination with lactic acid fermentation as described above is still recommended, as it is only through lactic acid fermentation that the liquid manure is disinfected and pathogenic bacteria are killed off.

Manure treatment during the year

To maintain the microbial environment in the manure pit, the liquid manure added each day has to be inoculated with lactic acid bacteria. This can be done by adding approximately 0.1% sauerkraut juice and biochar by volume to the daily addition of fresh manure into the pit. The most effective way of doing is is spraying the sauerkraut juice directly in the cowshed using an automatic atomizing system. This ensures a healthy microbial environment already in the cowshed and is good not only for the manure but especially also for the livestock and for the people working in the shed.

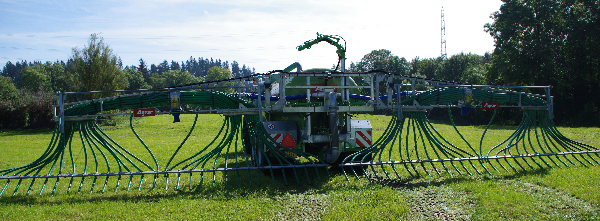

Treating slurry with biochar on the Holderstock farm. (Photo: Wilhelmine and Bruno Koller)

The climate in the cowshed will change already after a few days. It will stop smelling unpleasant. Also, the cattle will be noticeably calmer, and inflamed udders and hooves will cease swelling. Atomizing in the cowshed can be done completely automatically, with 2 litres of sauerkraut juice atomized every four hours per 100 livestock units.

Biochar in silage and feeds

Biochar too should be used in the cowshed as early as possible. Biochar can already be introduced into the feed silaging process. Biochar promotes lactic acid fermentation of the silage and prevents faulty fermentation. Less acetic acid and, in particular, less butyric acid are formed during the silaging process, reducing the risk of clostridia infections. The risk of fungus formation in the silage and of the related mycotoxins is also reduced. Biochar has a very high water holding capacity, which ensures good fermentation quality and prevents the production of butyric acid, especially in cases where the silage does not have enough time to wilt properly ( (e.g. bad weather) and at excessively low dry weight concentrations.

Overall, preservation quality is improved by moisture buffering. Thanks to biochar, there is little or no formation of fermentation juices, that are to be feared owing to the formation of butyric acid.

Biochar fixes pesticides and heavy metals that come with the biomass into the silage, where both negatively affect the fermentation environment and subsequently have a toxic effect on the animals. When present in the finished silage, biochar improves digestion and increases the energy conversion from the feed.

In using biochar in silage, only biochars registered as food additives and produced by licensed feed manufacturers may be used. Plants and charcoal have been used as feed additives ever since the early Iron Age to regulate digestion, in particular in ruminants. Biochar increases feed efficiency, which in turn increases the animals’ energy performance. Toxic substances are bound and the microbial environment in the digestive tract is stabilized. Biochar certified as feed can be added directly into the feed at 0.5%. To prevent the risk of blocking essential nutrients, feeding of biochar should be interrupted every 14 days for at least 5 days.

Summary

The combined use of biochar and lactic acid bacteria leads to improved animal health and production capacity, stabilizes the climate in the cowshed, disinfects it and the liquid manure, prevents nutrient losses and greenhouse gas emissions and leads finally to a biologically efficient fertilization of farmland. Biochar is not a panacea, but by supplementing good farming practice can sustainably optimize processes, increase farming profitability and make a positive contribution to the environment.

- Please write us your comment -

×